Description

WHLT- 11D

Matco Aircraft Landing Systems produces a superior dual fork 11 inch tail wheel for use with tail dragger aircraft which require a high flotation tail wheel–the T-11D.

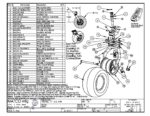

DIMENSIONS

The T-11D tail wheel has a eleven inch tubeless pneumatic tire and an overall length of 12.3 inches.Maximum width of this tail wheel with fully splayed arms is 7. inches and overall height is 14. inches.This cast aluminum tail wheel weighs 9.6 pounds.

FEATURES

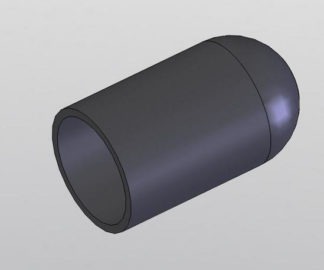

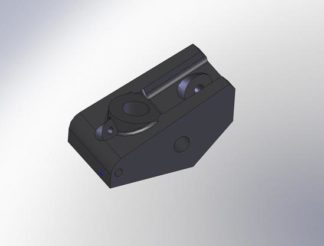

The T-11D tail wheel utilizes a dual fork configuration and incorporates a geometric release mechanism that allows the wheel to caster after reaching a steered angle of 40 degrees (earlier release available with optional steering arms WHLT-03A). The MH5N-S wheel used on the WHLT-11D has a .625 precision sealed ball bearing which is rigorously tested and designed to resist bearing fatigue providing a long bearing life.The arms and wings of the tail wheel fork assembly are composed of 4130 which is heat treated to a Rockwell 38-43 to ensure strength and are irridited to prevent corrosion. The tail wheel base and forks are machined extrusion and then black anodized to prevent corrosion as well.The wheel halves are spun aluminum for light weight and superior strength.The T-11D features split rims for ease of mounting and dismounting its 11×6-5 tubeless tire assembly.

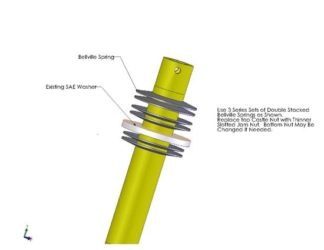

The tail wheel assembly is both steerable and full swiveling and provides easy installation with variant spring tension.This wheel has been designed to release with light spring tension and can accommodate a 1.75 inch wide spring (Use part number WHLTWBADT1.5 adapter for 1.5 inch wide springs plus WHLTWBADT1.25 for 1.25 inch wide). The optional WHLTWBED base is available for springs requiring two bolts for mounting.The assembly should be mounted on the flat spring so that the pivoting axle is as close to vertical as possible when the plane is loaded.All assembly bushings are made of oil impregnated brass so no lubrication is needed during the life of the tail wheel.In addition, the shaft has been redesigned to .625 for added strength and durability.

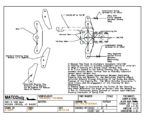

See the drawing below for explanation of how the GEOMETRIC RELEASE works

tailwheel5

tailwheel5 t11dassy

t11dassy TWVRTLDDWG

TWVRTLDDWG