What Is a Nosewheel Assembly

A nosewheel assembly is the wheel at the front of an aircraft and its associated family of components. The nosewheel assembly, which includes the wheel, the tire, and the steering mechanism, is a critical part of the larger landing gear assembly. On many aircraft, the nose gear is part of what is referred to as a “tricycle configuration,” with a single wheel at the nose and two wheels at the rear supporting the aircraft’s weight.

The nosewheel assembly is involved in a wide range of important aircraft functions, such as balance, steering, taxiing, takeoff, and landing.

Types of Nosewheels

While there is tremendous variation between nosewheel steering systems, most can be placed into one of two categories: steerable nosewheels and castering nosewheels.

Steerable Nosewheels

Steerable nosewheels are turned via rudder pedals to control the direction of the aircraft when it’s on the ground. Steerable nosewheels assemblies tend to be heavier than castering assemblies and a bit more complicated to install, since the assembly must be connected to the rudder pedals. Steerable nosewheels also offer more direct, finer control when steering.

Castering Nosewheels

Castering nosewheel steering systems are simpler, cheaper, and usually easier to install. There are no steering linkages to contend with during the installation process, since the wheel rotates and swivels freely. Castering nosewheels are highly moveable but can be challenging to control directionally for pilots who are first learning. Generally, castering nosewheels are controlled via differential braking.

Castering nosewheels are most often used in light general aviation aircraft or older aircraft. They are somewhat less commonly used than steerable nosewheels.

Factors to Consider

It’s worth noting that nosewheel steering systems are far less interchangeable than other aircraft assemblies. For the most part, nose gear decisions are made during the design process. Attempting to engineer an aircraft between steerable and free castering requires considerable engineering, which can be a complicated, risky process.

These days, most kit manufacturers opt for steerable nosewheel assemblies over castering. However, there are still multiple factors to consider when making a choice.

Compatibility with Your Aircraft

Basic compatibility with your aircraft is the first variable to consider when choosing a nosewheel assembly. It is very important to determine whether your kit is engineered for a steerable nosewheel or a castering nosewheel.

Load Rating and Weight Capacity

In the world of flight, weight capacity is about much more than basic weightbearing. Takeoff and landing put considerable load on an aircraft’s landing gear, including the nosewheel assembly. All landing gear components must be able to withstand those forces. It is critical to determine whether the nosewheel assemblies you are considering are rated to your aircraft and can safely support takeoff and landing.

Material and Construction Quality

As is virtually always the case with homebuilt aircraft components, material and construction quality are important considerations. Opting for quality materials can meaningfully extend the lifecycle of aircraft components, which is especially valuable in aerospace, where service environments can be intense.

Maintenance and Serviceability

Kit builders vary in terms of how much aircraft maintenance they like to do themselves versus what they prefer to outsource to a professional. When choosing a nosewheel assembly, it’s important to choose one that offers the level of accessibility and ease you want. This is also important to consider from an installation perspective. Some options are much easier to install than others.

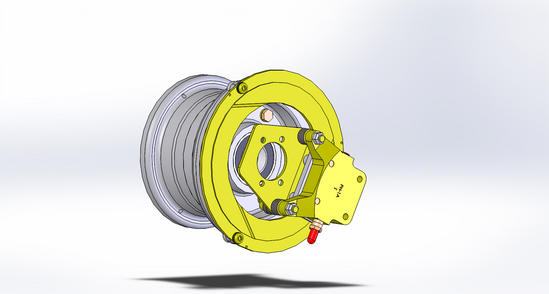

Matco ALS Nosewheel Assembly Options

Matco ALS is proud to offer three different categories of nosewheel assemblies for homebuilt aircraft. There are no noteworthy advantages of choosing one variety over another, though their weightbearing capacities are different. Customers generally choose based on weight rating and preferred look.

Diecast Nosewheel

Diecast nosewheels are made by pouring melted metal into a specialized die. The tires used in diecast nosewheel assemblies use tubes, akin to a bicycle tire.

Centrifugally Cast Nosewheel

When making a centrifugally cast nosewheel, the mold is spun to eliminate void and achieve the desired roundness. Like diecast nosewheels, centrifugally cast nosewheels use tires with tubes.

MH Series Nosewheel

Nosewheels from Matco ALS’s MH series are spun and formed over a mandrel. They are thin-walled, lightweight, and strong. MH series nosewheels are compatible with both tubeless and tube tires.

Shop Matco ALS Nosewheel Assemblies

Matco ALS is proud to be a long-time, trusted provider of nosewheel assemblies for homebuilt aircraft. We make both steerable and free castering assemblies in a wide range of weight ratings, so you can get the precise functionality and look you want for your plane. All Matco ALS nose gear is made by experienced machinists at our fully equipped facility in Utah.

Ready to choose your nosewheel assembly? Shop now.